Product classification

- Product Description

-

- Commodity name: H48508SNG

- Commodity ID: 1131280532080578560

P/N TE0604TA Product Description Lan transformer,DIP Number of Ports Single Speed 10BASE-T POE Rating NON-POE Rev A0 NOTES 1.RoHS Compliant; 2.Designed to meet IEEE802.3 requirements; 3.Storage Temperature:-40℃ To 120℃,Operating Temperature: -40℃ To 110℃; 4.SRP: Conforms to IPC/JEDEC J-STD-020; 5.Solderability:Conforms to ANSI/J-STD-002; 6.Packaging with tubes. Electrical Specification at 25℃ Parameter Specifications OCL 350uH Min(100KHz,0.1V With 20mA DC Bias) 675uH Min(100KHz,0.1V) LL 0.8uH Max(100KHz,0.02V) Pin1-5 shorted(Pin6-4-2) Turns Ratio 0.55uH Max(100KHz,0.1V) DCR 0.60Ω Max Hi-Pot PRI To SEC(600Vrms 1mA 60Sec) Schematic Dimensions Http://www.mag-tek.com.cn E-mail: sales@mag-tek.com.cn Tel: 86-769-86636536 Address: QingFeng East Road 511#, Shijie Town, Dongguan City, Guangdong Province.

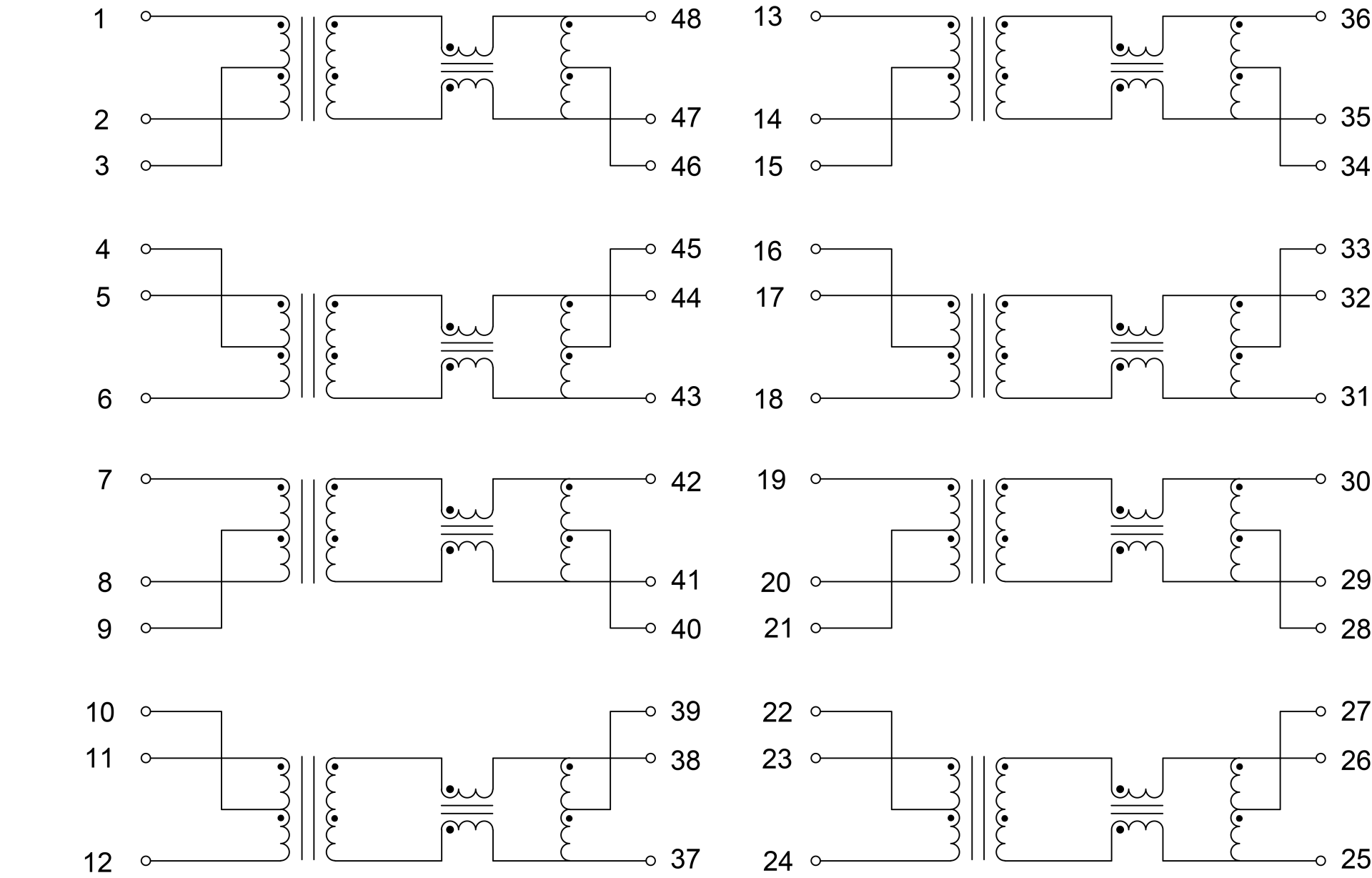

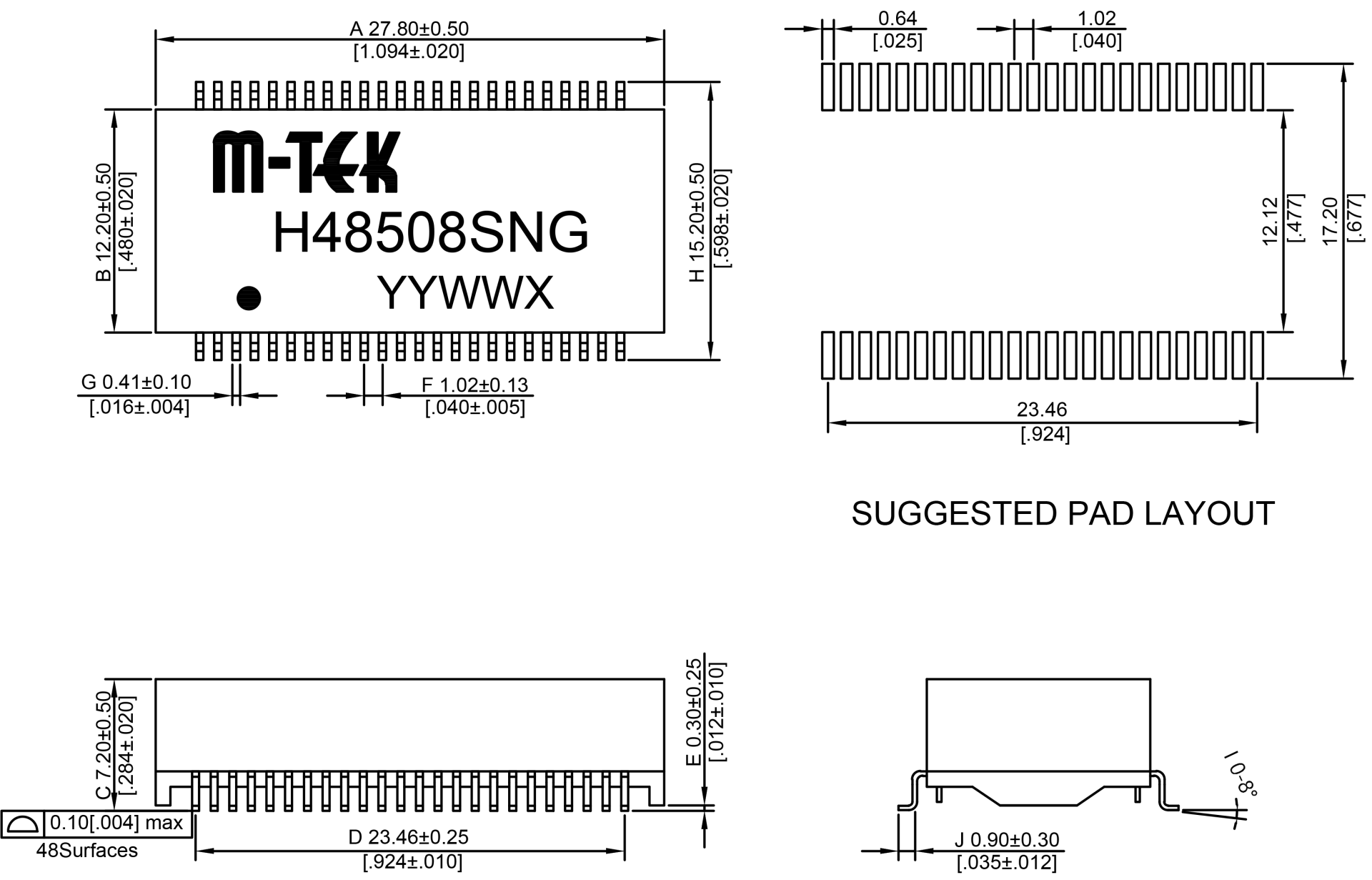

P/N H48508SNG Product Description Lan transformer, SMT Number of Ports Quad Speed 10/100BASE-T POE Rating NON-POE Rev A0 NOTES

1.RoHS Compliant;

2.Designed to meet IEEE802.3 requirements;

3.Storage Temperature:-40℃ To +85℃,Operating Temperature:0℃ To +70℃;

4.SRP: Conforms to IPC/JEDEC J-STD-020;

5.Solderability:Conforms to ANSI/J-STD-002;

6.Packaging with tapes and reels.Electrical Specification at 25℃ Parameter Specifications OCL 350uH Min(100KHz,0.1V With 8mA DC Bias) LL 0.5uH Max(100KHz,0.1V) Turns Ratio 1:1±5% DCR 1.4Ω Max Hi-Pot PRI To SEC(1500Vrms 1mA 60Sec) Insertion Loss -1.2dB Max(1-100MHz) Return Loss 1-30MHz 40MHz 50MHz 60MHz 80MHz -16dB Min -16dB Min -14.1dB Min -12.5dB Min -10dB Min Cross Talk 60MHz 100MHZ -33dB Min -28dB Min Common Mode Rejection 30MHz 60MHz 100MHz -40dB Min -35dB Min -30dB Min Schematic Dimensions

Http://www.mag-tek.com.cn

E-mail: sales@mag-tek.com.cn

Tel: +86-769-86636536

Address: QingFeng East Road 295#, Shijie Town, Dongguan City, Guangdong Province.

Classification:

Key words:

wound common mode filter

The integrally formed inductor includes a base body and a winding body, that is, the winding body is embedded in the metal magnetic powder and then pressed and cast. The SMD pin is directly formed on the surface of the base body as the lead-out pin of the winding body, which mainly solves long-term operation under high current conditions and can stably supply power and filter. As the volume of electronic products becomes smaller and smaller, the power becomes larger and the electronic components become smaller, the development of high power. The integrated inductor is also developing simultaneously. The smaller the volume, the more suitable it is for other industries. The development of integrated inductor in the future is infinite and huge, and it can replace the traditional I-shaped inductor, glue-shielded inductor and magnetic-shielded inductor.

Related Products

Solutions for your industry, ready for your choices